In research that could lead to next-generation energy storage systems, a team of Foundry scientists and users have developed a way to make a new kind of supercapacitor. By coating carbon nanotube electrodes with titanium disulfide, the researchers developed a method to create a supercapacitor with the highest energy density of any comparable system. The team, led by Dr. Xining Zang from Professor Liwei Lin’s group at UC Berkeley, recently published their work in Advanced Materials.

Capacitors are electrical components that store energy and are widely used in electronic devices. Typical supercapacitors, named for their ability to store more electrical charge than standard capacitors, store charge “physically” through the buildup of charges on their surfaces. On the other hand, pseudocapacitors can store charge “chemically” through redox reactions where one species transfers electrons to another, similar to a battery.

Pseudocapacitors can store as much charge as some batteries, however, while a battery charges and discharges over a timescale of hours (e.g. charging and using your cell phone or laptop), psuedocapacitors can operate much faster, on the scale of tens of seconds to several minutes. Supercapacitors often show high power density and long operation lifetimes, but are limited by having low energy density. While psuedocapacitors have been shown to store more energy, their widespread use has been hampered by their narrow electrochemical voltage window, the voltage range where the electrode materials are stable.

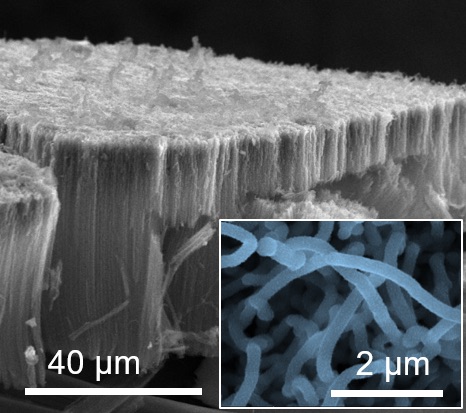

On its own, titanium disulfide is light, cheap, and has many potential benefits if used in a lithium-based energy storage system, but the material degrades rapidly and has relatively low conductivity. It’s been previously shown that coating nanocrystalline titanium disulfide onto vertically aligned carbon naotubes (VACNTs) can form highly conductive, three-dimensional porous networks to improve electrical conductivity, increase surface area, and stabilize the electrochemical reactions. However, the existing methods for creating these psuedocapacitors have problems with uniform coverage, contamination, and high toxicity.

The researchers developed a two-step process that combines atomic layer deposition (ALD) with a chemical vapor deposition (CVD) process to make coated VACNT electrodes that have precisely defined nanostructures. When used with an ultra-high concentration lithium-ion electrolyte, the new supercapacitor has an operating voltage window three times larger than before, making it comparable to organic electrolyte systems. The hybrid supercapacitor also has the highest energy density of any other pseudocapacitor. The new capabilities could provide an alternative to lithium batteries.

The new fabrication method combining ALD and CVD also has the potential to be used to coat titanium disulfide or other transition metal materials onto a variety of substrates, leading to further advances in the next generation of energy storage systems.

Read the paper at Advanced Materials.