Lithium-sulfur batteries are promising candidates for replacing common lithium-ion batteries in electric vehicles since they are cheaper, weigh less, and can store nearly double the energy for the same mass. However, lithium-sulfur batteries become unstable over time, and their electrodes deteriorate, limiting widespread adoption.

Now, a team of researchers led by scientists at the Berkeley Lab’s Molecular Foundry have reported that a new lithium-sulfur battery component allows a doubling in capacity compared to a conventional lithium-sulfur battery, even after more than 100 charge cycles at high current densities, which are key performance metrics for their adoption in electric vehicles (EVs) and in aviation.

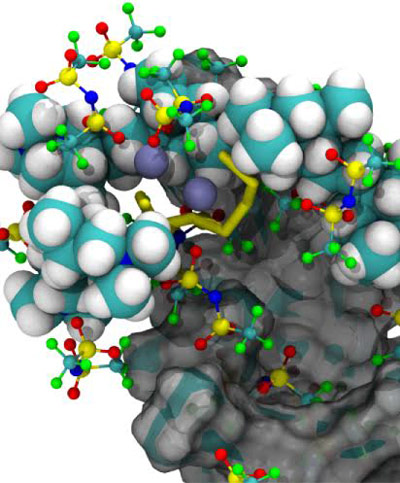

They did it by designing a new polymer binder that actively regulates key ion transport processes within a lithium-sulfur battery, and have also shown how it functions on a molecular level. The work was recently reported in Nature Communications.

When a lithium-sulfur battery stores and releases energy, the chemical reaction produces mobile molecules of sulfur that become disconnected from the electrode, causing it to degrade and ultimately lowering the battery’s capacity over time. To make these batteries more stable, researchers have traditionally worked to develop protective coatings for their electrodes, and to develop new polymer binders that act as the glue holding battery components together. These binders are intended to control or mitigate the electrode’s swelling and cracking.

The new binder goes a step further. Researchers from the Organic Synthesis Facility at the Molecular Foundry designed a polymer to keep the sulfur in close proximity to the electrode by selectively binding the sulfur molecules, counteracting its migratory tendencies.