We can directly see the hidden world of atoms thanks to electron microscopes, first developed in the 1930s. Today, electron microscopes, which use beams of electrons to illuminate and magnify a sample, have become even more sophisticated, allowing scientists to take real-world snapshots of materials with a resolution of less than half the diameter of a hydrogen atom.

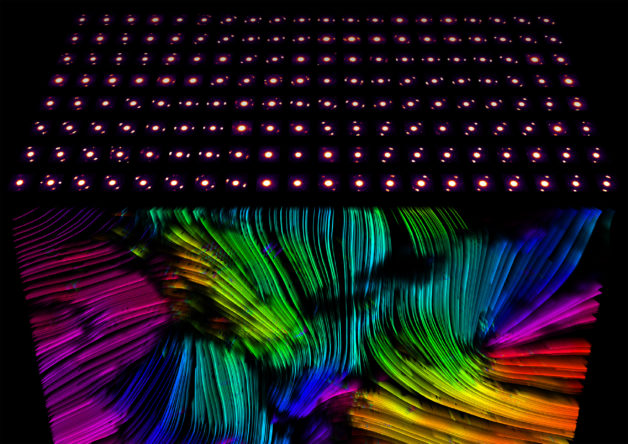

Now, Foundry scientists are pushing the boundaries of electron microscopy even further through a powerful technique called 4D-STEM, a term that stands for “2D raster of 2D diffraction patterns using scanning transmission electron microscopy.”

Their findings, reported in Nature Communications and Nature Materials, show for the first time how 4D-STEM can provide direct insight into the performance of any material – from strong metallic glass to flexible semiconducting films – by pinpointing specific atomic “neighborhoods” that could compromise a material’s performance, or perhaps have the potential to improve it.

In these studies, the researchers have shown that when 4D-STEM is deployed with the Foundry’s high-speed detectors, customizable algorithms, and powerful electron microscopes, the technique can help scientists map out atomic or molecular regions in any material – even beam-sensitive, soft materials – that weren’t possible to see with previous techniques.

In the Nature Materials study, the Foundry’s Andy Minor and co-authors demonstrated how high-speed detectors that capture atoms in action at up to 1,600 frames per second with 4D-STEM allowed unprecedented molecular movies of a small-molecule organic semiconductor. The movie showed how the molecular ordering in the semiconductor, often used in organic solar cells, changed in response to a common processing additive (called DIO or 1,8-diiodooctane) that is known to enhance solar cell efficiency.

Such details, which are not possible to observe with conventional STEM, are significant because low-angle boundaries – like long, straight tunnels through which a car can accelerate unimpeded at high speed – are necessary for electrons to couple and generate a charge in a functional semiconductor.

In the Nature Communications study, carried out as part of DOE’s Mechanical Behavior of Materials program, Andy Minor, Colin Ophus, and co-authors used 4D-STEM to pinpoint atomic-scale “weak links” in bulk metallic glass that ultimately lead to fractures under stress.

Regular metals are crystalline materials, which means that their atoms are arranged in a perfect, repeating pattern – like tennis balls perfectly stacked inside a cube so that they fill up the space. When an atom is missing such a defect is obvious under an electron microscope, making it easier to predict where a material might be compromised.

But bulk metallic glasses (BMGs) are amorphous, meaning that their atoms form a disordered pattern – like a randomly assembled, unstable pile of tennis balls, golf balls, and baseballs tossed inside a box. And this unpredictable structure is what makes it hard for materials scientists to figure out where those atomic defects might be hiding as they compromise a material’s toughness.

By using 4D-STEM with high-speed electron detectors, the researchers measured the average spacing between atoms within certain regions of the BMG material, and recorded the “strain” or change in this spacing as the material is pulled until it breaks.

They showed that 4D-STEM, when combined with high-speed electron detectors and fast algorithms to analyze hundreds of thousands of diffraction patterns throughout a sample, can identify the precursors in the material’s atomic structure that cause it to fail.