Adapted from this Penn State press release

It started with a mystery: How did molten salt breach its metal container? Understanding the behavior of molten salt, a proposed coolant for next-generation nuclear reactors and fusion power, is a question of critical safety for advanced energy production. The multi-institutional research team of Foundry staff and users initially imaged a cross-section of the sealed container, finding no clear pathway for the salt appearing on the outside. The researchers then used electron tomography, a 3D imaging technique, to reveal the tiniest of connected passages linking two sides of the solid container. That finding only led to more questions for the team investigating the strange phenomenon. They published the answers recently in Nature Communications.

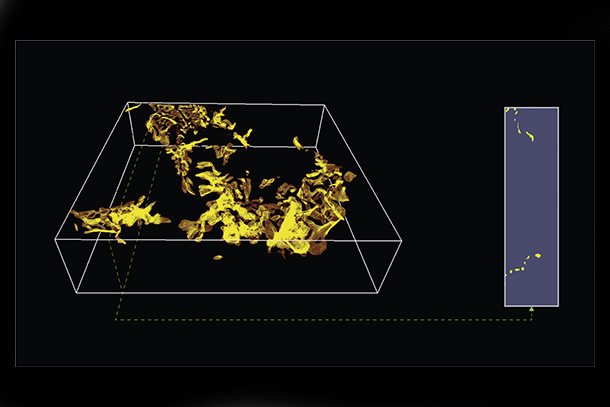

Corrosion, a ubiquitous failure mode of materials, is traditionally measured in three dimensions or two dimensions, but those theories were not sufficient to explain the phenomenon in this case,” said co-corresponding author Yang Yang, Foundry user and assistant professor of engineering science and mechanics and of nuclear engineering at Penn State. “We found that this penetrating corrosion was so localized, it only existed in one dimension — like a wormhole.

Wormholes on Earth, unlike the hypothetical astrophysical phenomenon, are typically bored by insects like worms and beetles. They dig into the ground, wood or fruits, leaving one hole behind as they excavate an unseen labyrinth. The worm may return to the surface through a new hole. From the surface, it looks like the worm disappears at one point in space and time and reappears at another. Electron tomography could reveal the hidden tunnels of the molten salt’s route on a microscopic scale, whose morphology looks very similar to the wormholes.

To interrogate how the molten salt “digs” through metal, the team developed new tools and analysis approaches. According to Yang, their findings not only uncover a new mechanism of corrosion morphology, but also point to the potential of intentionally designing such structures to enable more advanced materials.

“Corrosion is often accelerated at specific sites due to various material defects and distinct local environments, but the detection, prediction and understanding of localized corrosion is extremely challenging,” said co-corresponding author Andrew M. Minor, director of the Foundry’s National Center for Electron Microscopy.

Interested in Becoming a Foundry User?

Join our collaborative, multidisciplinary environment.

Learn more >

The team hypothesized that wormhole formation is linked to the exceptional concentration of vacancies — the empty sites that result from removing atoms — in the material. To prove this, the team combined 4D scanning transmission electron microscopy with theoretical calculations to identify the vacancies in the material. Together, this allowed the researchers to map vacancies in the atomic arrangement of the material at the nanometer scale. The resulting resolution is 10,000 times higher than conventional detection methods, Yang said.

Molten salt, which can be used as a reaction medium for materials synthesis, recycling solvent and more in addition to a nuclear reactor coolant, selectively removes atoms from the material during corrosion, forming the 1D wormholes along 2D defects, called grain boundaries, in the metal. The researchers found that molten salt filled the voids of various metal alloys in unique ways.

Now that the researchers better understand how the molten salt traverses specific metals — and how it changes depending on the salt and metal types — they said they hope to apply that physics to better predict the failure of materials and design more resistant materials.

Read the full press release