By Alison Hatt

Of all the research labs found at an average university, those performing chemical reactions are among the most dangerous. The chemicals used can be toxic or highly reactive, causing sudden changes in pressure or temperature, and accidents can be fatal.

These risks pose a particular challenge at user facilities like the Molecular Foundry, where hundreds of researchers, many of them students, come to work in chemistry labs every year.

Synthetic chemistry is one of the Molecular Foundry’s specialties, and users often come to the facility with ambitious goals in organic, inorganic, and biological synthesis, involving experimental reactions with little precedent in the scientific literature.

Molecular Foundry staff, to whom safety is as important as scientific excellence, have developed a highly effective system for identifying and mitigating the hazards involved in chemical research to support these users. A team of staff members recently detailed that approach in the Journal of Chemical Education, hoping to help other researchers, particularly students, improve chemical safety at their own institutions.

Central to the Molecular Foundry’s chemical safety process is a simple innovation: a form that walks users through the hazard-analysis process for chemical reactions. Tracy Mattox, lead author of the paper, helped spearhead implementation of the chemical safety form when she was a Scientific Engineering Associate at the Molecular Foundry.

“We have people from all over the world coming to the Foundry, from all kinds of backgrounds and with varying levels of experience,” said Mattox. “Our chemical safety process is about establishing trust between the supervisor and the user, empowering the user to work safely within set parameters so they feel a sense of ownership over their research.”

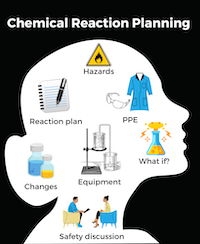

The form asks detailed questions about a planned chemical reaction. What chemicals will be used, in what quantities and concentrations, and what are the associated hazards or special handling requirements? What instruments or techniques will be used, and do they entail additional training? What could go wrong, how can it be prevented, and how should you respond if it does? In addition to completing all required training, a user must think through and answer the questions in the form to the satisfaction of their supervisor before starting work.

Perhaps most critically, the form prompts the user and their supervisor to establish triggers for reevaluation. In other words, as the user explores or refines the reaction to achieve their research goals, at what point will they have strayed so far from the original plan as to require further safety analysis with their supervisor?

Completing the form requires running numerous mental simulations, employing both creativity and technical knowledge, as well as reading the relevant Safety Data Sheets for any chemicals used. The form serves as a guide to safety discussions between the user and their supervisor and sets up the user to explore a reaction within clearly defined limits, knowing at what point additional discussions will be needed.

“We sometimes get pushback from users, who object to the time investment required,” said Mattox. “But then I’ll hear from them later, after they leave, saying they understand now why we do it and that they’re implementing it in their own lab!”

The Molecular Foundry’s chemical safety form follows the Department of Energy’s Integrated Safety Management (ISM) process for hazard evaluation, required for all work at DOE labs. For researchers like Mattox, who have years of experience practicing ISM, the hazard evaluation process becomes second nature. By codifying that process in a simple form, the Molecular Foundry ensures that all researchers in their chemistry labs perform ISM at a similar level, regardless of prior experience and duration of their project.

Interested in Becoming a Foundry User?

Join our collaborative, multidisciplinary environment.

Learn more >

“Operating as a User Facility, we aim to help the broadest and most diverse pool of scientists possible,” said co-author Jeff Urban, Director of the Molecular Foundry’s Inorganic Nanostructures Facility. “We can’t possibly ask everyone to learn new habits in such a short time, but we can give them important guiding tools such as ISM to allow them to safely access the wide range of tools available at the Foundry and partner safely with staff.”

The form has proved useful outside of the chemical synthesis labs as well. At the Molecular Foundry’s National Center for Electron Microscopy, the form has been adapted for preparation of liquid samples and samples of air-sensitive materials like lithiated battery electrodes. As in the synthesis labs, these types of experiments can present new hazards as the sample volume is increased or chemical substitutions are made, and the safety form makes sure that researchers think through the possible consequences in advance.

“This process has been amazingly effective at preventing accidents and injuries at the Foundry,” said Mattox. “So in the paper we give suggestions for how someone at a university could introduce the process in their own chemistry labs. If we can help make other labs safer as well, that’s a huge win.”

Download a blank copy of the ISM form used at the Foundry.