Adapted from this Berkeley Lab press release

New research has revealed the fundamental mechanisms that limit the performance of copper catalysts – critical components in artificial photosynthesis that transform carbon dioxide and water into valuable fuels and chemicals.

In a study led by Foundry users, researchers have used sophisticated X-ray techniques to directly observe how copper nanoparticles change during the catalytic process. By applying small-angle X-ray scattering (SAXS) – a technique traditionally used to study soft materials like polymers – to this catalyst system, the team gained unprecedented insights into catalyst degradation that has puzzled scientists for decades.

The CO2 electrochemical reduction reaction (CO2RR) process has intrigued scientists for decades as a promising way to make fuel and other important compounds. A big breakthrough in the 1980s identified copper as a high-performing catalyst for transforming CO2 and water into starting ingredients for liquid fuels and chemicals like ethylene and ethanol. Subsequent studies showed that copper contains active sites where electrocatalysis takes place: electrons from the copper surface interact with carbon dioxide and water in a sequence of steps that transform them into products like ethanol fuel and ethylene for plastics. Researchers are investigating ways to tune these active sites to selectively produce specific chemicals, including ethanol, ethylene, and propanol.

But copper’s super-catalytic properties quickly degrade during CO2RR, diminishing its performance over time. Through the years, researchers have looked for ways to prevent this performance loss, but the chemical and physical processes that control this degradation were unclear.

With this study – published recently in the Journal of the American Chemical Society – those processes are less mysterious thanks to an innovative application of scattering and imaging techniques that allowed the researchers to identify and observe two competing mechanisms that drive copper nanoparticles to the brink of degradation in a CO2RR catalyst: particle migration and coalescence (PMC), in which smaller particles combine into larger ones, and Ostwald ripening, where larger particles grow at the expense of smaller particles.

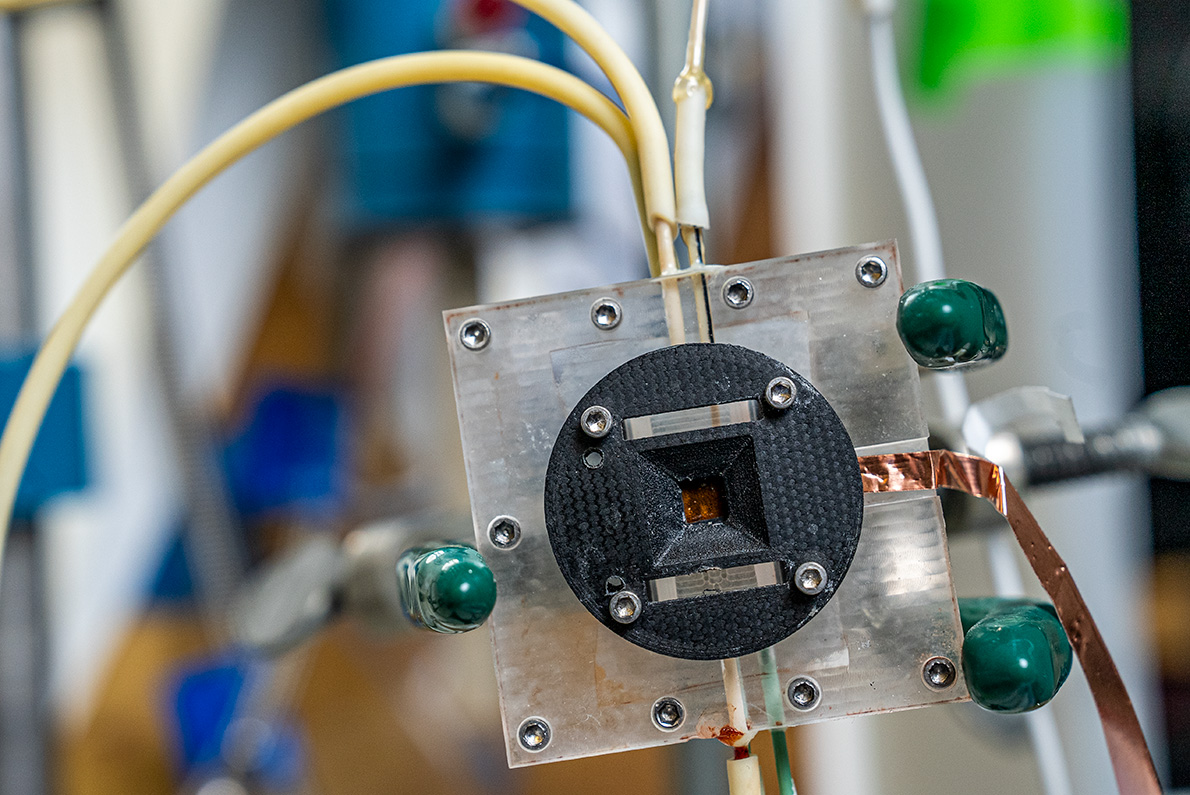

In this study, the researchers used a technique called small angle X-ray scattering (SAXS) at the Stanford Synchrotron Radiation Lightsource (SSRL) at SLAC to track the size and shape distributions of uniformly shaped 7-nanometer copper oxide nanoparticles under various electrical voltages in a custom-designed electrochemical cell with an aqueous electrolyte.

When running the CO2RR reaction for an hour, the researchers found that the PMC process dominates in the first 12 minutes, and then after that, Ostwald ripening takes over. Under the PMC mechanism, the nanoparticles migrate and coalesce into clusters. When the Ostwald ripening process takes over, smaller nanoparticles dissolve and redeposit onto larger nanoparticles, the same process that can create crunchy water crystals in ice cream.

Interested in Becoming a Foundry User?

Join our collaborative, multidisciplinary environment.

Learn more >

Further analyses in the current study showed that lower voltages, where reactions are slower, trigger the migration and agglomeration of the PMC process – and larger voltages speed reactions up, increasing the dissolution and redeposition process of Ostwald ripening.

Separate in situ X-ray absorption spectroscopy (XAS) measurements at SSRL show that the copper-oxide nanoparticles reduce to copper metal before restructuring begins, and post-mortem imaging confirmed that the nanoparticles had migrated and formed large agglomerates. The imaging was achieved using advanced electron microscopy techniques at the Foundry.

Read more in the full press release.