If you add more lithium to the positive electrode of a lithium-ion battery – overstuff it, in a sense – it can store much more charge in the same amount of space, theoretically powering an electric car 30 to 50 percent farther between charges. But these lithium-rich cathodes quickly lose voltage, and years of research have not been able to pin down why – until now.

After looking at the problem from many angles, a team of Foundry scientists and users created a comprehensive picture of how the same chemical processes that give these cathodes their high capacity are also linked to changes in atomic structure that sap performance. The team also includes researchers from SLAC National Accelerator Laboratory (SLAC), Stanford University, and battery manufacturer Samsung.

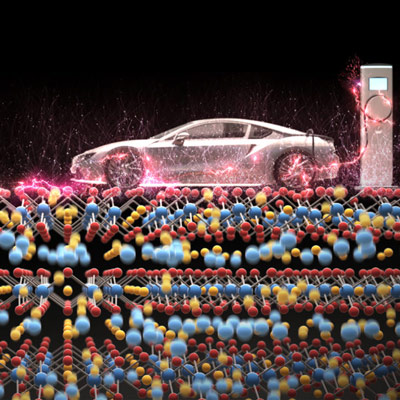

Batteries convert electrical energy to chemical energy for storage. They have three basic parts – two electrodes, the cathode and the anode, and the liquid electrolyte between them. As a lithium-ion battery charges and discharges, lithium ions shuttle back and forth between the two electrodes, where they insert themselves into the electrode materials.

The more ions an electrode can absorb and release in relation to its size and weight – a factor known as capacity – the more energy it can store, and the smaller and lighter a battery can be, allowing batteries to shrink and electric cars to travel more miles between charges.

Like today’s cathodes, lithium-rich cathodes are made of layers of lithium sandwiched between layers of transition metal oxides – elements like nickel, manganese, or cobalt combined with oxygen. Adding lithium to the oxide layer increases the cathode’s capacity by 30 to 50 percent.

The Foundry’s David Prendergast noted that removing all of this lithium can make the material unstable, though. “It’s like taking all of the bricks out of a building – there’s not a lot to hold it up,” he said.

Previous research had shown that several things happen simultaneously when lithium-rich cathodes charge; lithium ions move out of the cathode into the anode. Some transition metal atoms move in to take their place. Meanwhile, oxygen atoms release some of their electrons, establishing the electrical current and voltage for charging. When the lithium ions and electrons return to the cathode during discharge, most of the transition metal interlopers return to their original spots, but not all of them and not right away. With each cycle, this back and forth changes the cathode’s atomic structure. It’s as if the bucket morphs into a smaller and slightly different bucket.

The team is already working toward using the fundamental knowledge they have gained to design battery materials that can reach their theoretical capacity and not lose voltage over time. One aim in ongoing R&D will be to find ways to stabilize the framework for the lithium by preventing wandering atoms from getting stuck and obstructing flow during charge and discharge.