When the inside of a mollusk shell shimmers in sunlight, the iridescence isn’t produced by colored pigments but by tiny physical structures self-assembled from living cells and inorganic components. Now, a team of researchers at the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) has developed a platform to mimic this self-assembly ability by engineering living cells to act as a starting point for building composite materials.

Engineered living materials (ELMs) use living cells as “materials scaffolds” and are a new class of material that might open the door to self-healing materials and other advanced applications in bioelectronics, biosensing, and smart materials. Such materials could mimic emergent properties found in nature – where a complex system has properties that the individual components do not have – such as iridescence or strength.

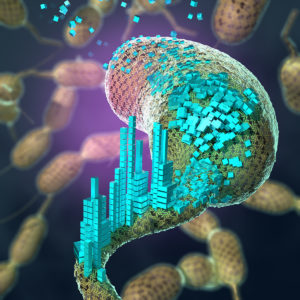

Borrowing from this complexity seen in nature, the Berkeley Lab researchers engineered a bacterium that can attach a wide range of nanomaterials to its cell surface. They can also precisely control the makeup and how densely packed the components are, creating a stable hybrid living material. The study describing their work was recently published in ACS Synthetic Biology.

Both natural structures and the ELMs they inspire are made up of hierarchical patterns of materials. This means that for a material made of regularly sized building blocks, each big block is made of smaller blocks, and each of the smaller blocks is made of even smaller pieces. For example, mollusks build their shells out of superthin “platelets” just 500 nanometers thick, and each platelet is made of millions of tiny nanograins with a diameter of just 30 nanometers.

To control the self-assembly of these types of structures on the surface of living cells, Ajo-Franklin and her team took advantage of surface-layer (S-Layer) proteins to form ordered, sheet-like structures on the surface of many microbes.

The researchers chose the bacterium Caulobacter crescentus since it can survive low-nutrient and low-oxygen conditions, and its S-Layer protein, RsaA, because it is very well-studied. The team engineered RsaA with a biological “lock and key” system to precisely control where and how densely materials attach to the cell surface.