By Laurie Chong

In their second publication focused on laboratory safety and safe nanoparticle handling practices, a team of Foundry staff have developed detailed guidance on optimizing inorganic synthesis equipment placement inside a fume hood in order to protect the breathing zone while working. The team previously published guidance for safe nanoparticle waste handling practices.

Tracy Mattox, Carleton Falzone, Tevye Kuykendall, and Jeff Urban worked with Sasan Sadrizadeh from the Center for Built Environment at UC Berkeley to study how obstructions within a fume hood can affect airflow patterns and potentially impact the breathing zone. Their work was recently published in Annals of Work Exposure and Health.

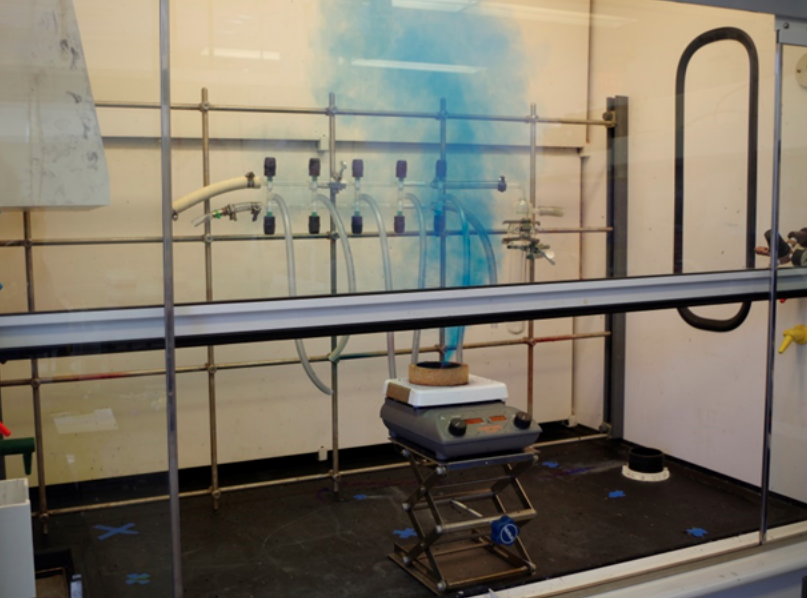

The research team identified a knowledge gap with respect to fume hood safety – the influence that internal obstructions, like a typical synthetic reaction setup, have on airflow. Industry standards and safety guidelines are based on the performance of an empty fume hood. It was unknown how typical synthesis equipment in a constant velocity fume hood may impact the airflow, and thus, the movement of nanoparticles and hazardous chemicals inside the hood.

“A fume hood is the most central piece of safety equipment available to researchers in a laboratory environment,” said Tracy Mattox, lead author and Principal Scientific Engineering Associate at the Foundry. “While we know that the face velocity and sash height can strongly influence air patterns, there are few specific recommendations that can be given to researchers to guide them to maximize the safety of their particular hood.”

The researchers found that it is possible to position common inorganic synthesis equipment in such a way that forces air beyond the hood sash and into the researcher’s breathing zone, creating a potentially dangerous situation. Additionally, they found that a Schlenk line can drastically change the airflow patterns around the tubing and glassware, giving any released chemicals additional time to mix together before they are removed.

To protect the breathing zone while working with chemicals in a constant velocity hood, the team developed the following recommendations:

- Keep the sash height slightly lowered (18”) to efficiently remove any released particles.

- Move reactions out from under sample boxes and other equipment installed on hood walls.

- Keep reactions as far back in the hood as feasible.

- Raise reactions slightly (above 8”) whenever possible.

- Be mindful that Schlenk lines keep airflow more concentrated around the reaction setup, so more mixing of chemicals is likely than in an obstruction-free hood.

At the Molecular Foundry, safety is integrated into the organizational culture because research that is safe is also innovative and productive. Learn more about safety at the Molecular Foundry.