By Brooke Kuei

Plastics can be found almost everywhere – in trash bags, water bottles, packaging materials, clothing, and more. Understanding mechanical properties, such as why trash bags are stretchy and what prevents a phone case from breaking, is what allows plastics to be used in so many different ways.

There is particular interest in improving a material’s ductility, its ability to be stretched without breaking. In a collaboration between the Molecular Foundry and Dow Inc, researchers have measured extreme ductility in films of the commodity plastic, polystyrene. Their work, which was recently published in Macromolecules, also demonstrates a new way of stretching freestanding thin films of plastic.

“Polystyrene is a classic brittle polymer. It is not supposed to be ductile at room temperature, but when tested in thin film form it kept stretching without breaking,” said Andrew Minor, facility director of the Foundry’s National Center for Electron Microscopy and Professor of Materials Science and Engineering at UC Berkeley. The researchers found that they were able to stretch thin films of polystyrene up to three times their original length without the material breaking.

One possible explanation for this extreme stretchiness may come from the process used to make the thin film – referred to as microtoming – where a large piece of plastic is sliced into thin slivers with a diamond knife. Because plastic is made up of long chains of repeating subunits, the researchers hypothesize that cutting the plastic introduces disorder to the chains, allowing them to slip past each other with more ease and stretch without breaking.

“Imagine a messy, knotted up ball of holiday lights,” explained Nathan Velez, graduate student and first author of the paper. “The chains in a glassy plastic are randomly entangled. If you start to pull on this material and only a few chains bear the load, they will reach a breaking point even if there is still slack between most of the entanglements. Microtoming introduces disorder, causing chains near the cut surfaces to have more wiggle room to move around. This prevents them from reaching their breaking point and as the slack between other entanglements is used up, the load is redistributed among more chains. I should note that I don’t recommend using this method to untangle your holiday lights.”

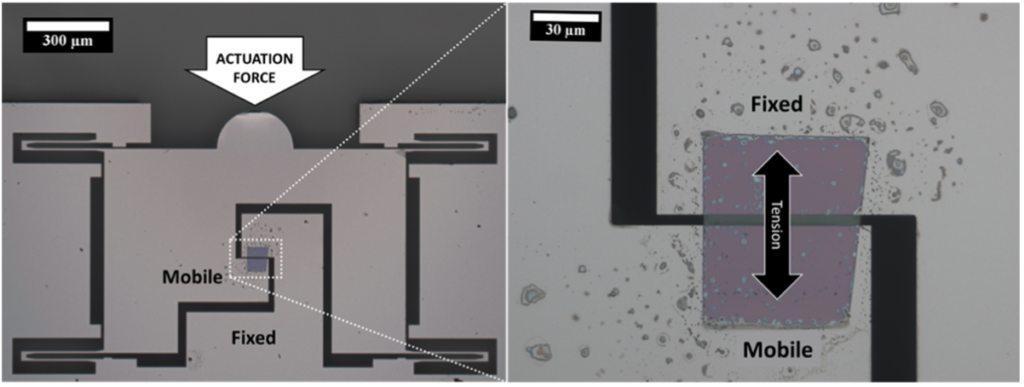

The researchers were able to make these measurements on freestanding thin films of plastic by using a push-to-pull device, which was developed in a previous collaboration between Hysitron, Inc and Andrew Minor. The push-to-pull device can stretch fragile, freestanding thin films of plastic because it is smaller than other mechanical testing methods, and also because it has a platform that can support the film and protect it until it is time to perform the test.

Optical images of an oversized push-to-pull (PTP) device with a microtomed polystyrene thin-film specimen. When the round “head” of the mobile region is actuated by a “pushing” force (left), the 4.5 μm wide horizontal gap between the mobile and fixed regions is expanded. This translates the actuation force into a tensile force applied to the sample (right). The thickness of the film shown is 240 nm.

“The most important technical achievement is the ability to place the freestanding films across the small gap in the device,” explained Andrew Minor. “The trick developed by Nate was frozen alcohol. It’s gooey when it’s frozen, so you can move the sample around and get it into position, and then when you heat it up it goes away, leaving behind the film in position.”

Moving forward, the researchers will study more brittle plastics to confirm if extreme ductility from microtoming is universal. Now that they have a method for testing freestanding films of plastic, they will also apply their mechanical testing technique to plastics used for applications at Dow, such as materials used in car bumpers.

“From an industrial perspective, these university interactions are very energizing and exciting and there is a lot of learning on both sides,” said Gregory Meyers, research fellow at Dow. “This was a very complementary arrangement, with the Minor group’s expertise in mechanical testing and push-to-pull devices and our expertise and interest in the polymer science.”

“It’s really been a joint project – some samples have literally flown back and forth,” added Minor. “I never would have explored this field without Dow’s motivation to learn more about the mechanics of their materials. I really like having industrial partners with fundamental questions about materials with real world applications, so it’s been a mutually beneficial collaboration.”

About Dow

Dow (NYSE: DOW) combines global breadth, asset integration and scale, focused innovation and leading business positions to achieve profitable growth. The Company’s ambition is to become the most innovative, customer centric, inclusive and sustainable materials science company. Dow’s portfolio of plastics, industrial intermediates, coatings and silicones businesses delivers a broad range of differentiated science-based products and solutions for its customers in high-growth market segments, such as packaging, infrastructure and consumer care. Dow operates 109 manufacturing sites in 31 countries and employs approximately 36,500 people. Dow delivered sales of approximately $43 billion in 2019. References to Dow or the Company mean Dow Inc. and its subsidiaries. For more information, please visit www.dow.com or follow @DowNewsroom on Twitter.