Digital infrastructure encompasses the entire life cycle of scientific data. This includes data acquisition, storage, analysis and sharing. The Foundry’s unique synthesis and fabrication capabilities add an additional layer of sample processing metadata and history to this data chain. This digital infrastructure has been identified as a critical theme that supports the scientific mission of the Foundry.

We have a Foundry-wide group of staff to support building new automated equipment, implementing data sharing and analysis pipelines, and building data support infrastructure. We help to translate user’s scientific and technical requirements into computing technologies.

Our team is working to build Foundry-wide tools for FAIR (Findable, Accessible, Interoperable, Reusable) data storage, analysis, and access, as well as work with Foundry scientists and users to develop and improve data workflows for domain specific problems.

Highlighted Projects

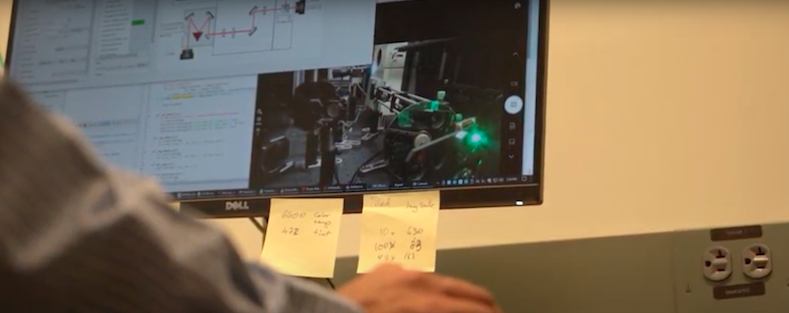

ScopeFoundry

ScopeFoundry is a Python platform for controlling custom laboratory experiments and visualizing scientific data developed at the Molecular Foundry. ScopeFoundry is currently used on a dozen microscopes and synthesis systems at the Foundry. Additionally ~10 groups are actively using ScopeFoundry to run their labs around LBNL and at academic institutions around the world. This unique capability of quickly iterating on custom instruments has allowed us to rapidly react to users’ needs. An example of this is laser annealing of microwave qubits from Irfan Siddiqi. Their group identified work at IBM that showed that laser annealing of qubit junctions may act as a tuning mechanism for junction resonance frequencies. Over the course of a week, we modified a ScopeFoundry microscope and built custom software to perform high throughput automated annealing of a wafer full of these qubits. This allowed their group to quickly identify optimal annealing conditions.

ML-enabled Autonomous Synthesis Workflows

Foundry scientists have recently demonstrated the ability of neural networks to learn time-dependent protocols for materials self-assembly and synthesis. This approach, based on a branch of machine learning called reinforcement learning, focuses on real-time control of instruments and is distinct from approaches that attempt to identify promising initial conditions for synthesis. We are currently implementing these algorithms into autonomous materials discovery workflows on several robotic synthesis systems, including liquid- and gas-phase synthesis tools. The result will allow autonomous experiments in which a user specifies an objective and the learning algorithm performs multiple syntheses, iteratively improving its time-dependent protocol, until the objective is attained.

Correlation Microscopy Workflows

Developing next-generation materials requires a deep understanding of structure-property relationships at many length scales. This in-turn necessitates the ability to acquire and cross-correlate data acquired through a range of microscopy and spectroscopy techniques in a high throughput manner. We are developing a universal platform that allows users to send a single sample to different characterization laboratories throughout the Foundry and ultimately acquire a cross-correlated data set that can produce novel structure-property insights.