Separating air into its primary components, typically nitrogen and oxygen, is an energy intensive process that involves fractional distillation at cryogenic temperatures. Alternative membrane-based gas separation technologies have the potential to decrease energy costs five-fold. However, membranes in use today are incapable of simultaneously achieving high permeability and high selectivity in the process, and thus the cost of membrane-based air purification systems remains prohibitively high.

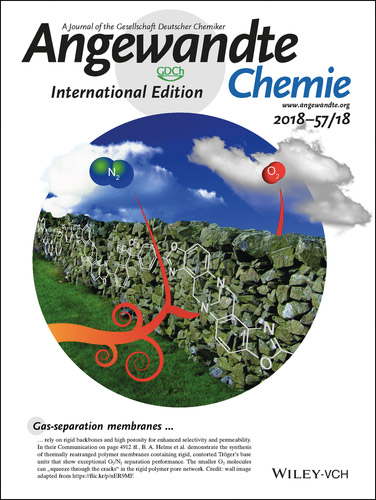

To address this problem, a team of Foundry staff and users developed a new polymer membrane for air separations, which surpasses the oxygen–nitrogen permselectivity upper bound set by competing membrane platforms. In turn, air purification systems implementing them would occupy smaller footprints and cost less. Their work was recently featured on the back cover of the journal Angewandte Chemie.

Their design is based on a new family of thermally rearranged polymer membranes that feature a high degree of pore rigidity at sub-nanometer length scales, which is critical to enforcing gas permeation selectivity. Unfortunately, rigid pore architectures are typically not possible with conventional polymers. Therefore, the researchers devised a clever strategy to access them through chemical transformations of the polymer chains comprising the membrane, which then enhanced its permselectivity for oxygen via a size-sieving mechanism.

In addition to providing new avenues for large-scale air separations, these membranes could also lead to better on-board inert-gas generation systems. For example, air separation membranes are used to remove oxygen from air before backfilling commercial airliner fuel tanks, minimizing the risk of an accidental explosion. The new membranes would allow for smaller, more efficient membrane-based modules.